Are you looking for machines and equipment for laboratory use, for small scale production, validation, proofing, colour matching or in another way want to test how a coating or an ink would transfer to a substrate? Maybe you simply need Samples for Colour Matching, Samples for Customer Approval or Printability Testing? Below is a range of products that can help you with that.

VCML Lab/Pilot Coater

The VCML is a precision engineered coating machine, designed to print, coat and laminate all types of flexible webs such as papers, films, and metallic foils on a reel-to-reel basis. With the ability to apply various coatings such as inks, paints, varnishes, adhesives both solvent and water based, by various application methods, this makes the VCML particularly useful for product development, quality control and small scale production for low volume of a specialised product.

- Designed to print, coat and laminate all types of flexible webs.

- For solvent, water and UV based applications.

- Coating and printing systems easily interchangeable.

- Touch screen control system with graphical set up and operating system.

- Servo drive with a speed range of 1–50m/min.

- Rigid aluminium framework.

- Integrated electrical and pneumatic controls.

A selection of Standard Printing/Coating Processes are available, which can be configured to a variety of coating methods and satisfy a wide range of applications. These coating and printing systems are easily interchangeable.

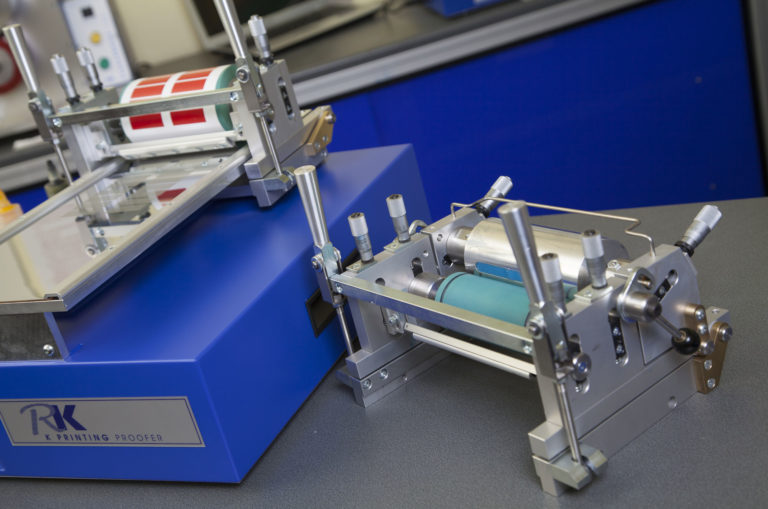

K Printing Proofer

High quality proofs using gravure, gravure-offset or flexo inks are produced instantly using the K Printing Proofer. Featuring electronically engraved printing plates and variable printing speeds of up to 40m/min, this is an essential tool for all those involved in the manufacturing or use of liquid inks. Ideal for R&D and computer colour matching data, quality control and presentation samples. The K Printing Proofer is very easy to clean and all parts are solvent resistant.

Results ideal for computer colour matching or spectrophotometer readings.

High quality proofs using gravure, gravure-offset or flexo inks are produced instantly using the K Printing Proofer.

Almost any flexible substrate can be printed or laminated.

Excellent printability ensured by micrometer control.

Multiple ink samples may be printed simultaneously for comparison purposes.

High printing speeds enable use of inks nearing press viscosity.

Easy to operate with a footprint of just 400 x 500mm

Flexiproof 100/UV

The FlexiProof 100 offers a high speed, operator-friendly machine for the production of proofs using water, solvent or UV flexographic inks. It is an essential tool for all those involved in the manufacture and use of flexo inks. Ideal for quality control testing to ensure consistency of performance of inks and substrates over time, presentation samples, printability of substrates, R&D including product and commericial viability, and computer colour matching data.

- Printers – eliminates press downtime by colour matching off press.

- Can be used to determine performance properties, i.e. wear resistance, scratch resistance, flexibility, durability, gloss, etc.

- Will print on all typical commercial substrates- paper, film, foil.

- Minimises expensive on-press waste production, boosts customer confidence and minimises customer returns.

- Inks – computer colour matching, database and sample preparation.

- Eliminates the need to use a production line printing press for pilot runs, as the Flexiproof 100 is a scaled down but exact version of a full sized flexo press.

- Research and development – product viability, commercial viability.

- Now available with UVLED curing capabilities.

Complies with ISO 2834-2

Results are ideal for computer colour matching or spectrophotometer readings.

K303S Multi Coater

The K303S enables accurate and reproducible prints and coatings to be made using a wide range of products, and many different substrates. The different heads detailed below are fully and easily interchangeable, providing Gravure, Flexo and exceptionally accurate surface coatings and lamination. The smallest differences in products can be detected by applying multiple samples adjacent to each other.

Coating speed 1 – 40m/min.

Re-designed in 2022, the base unit includes fully integrated servo drive and touch screen control.

Easily repeatable samples.

Interchangeable heads.

Multiple coatings simultaneously for comparison.

Maximum coating area 350 x 440mm when bar coating.

K Lox Proofer

The simplest method of applying flexo inks and other fluid coatings onto any substrate to produce accurate and repeatable proofs that closely resemble conventional flexo printing. The K Lox Proofer is an essential tool for ink makers and printers alike. Ideal for quality control and presentation samples, R&D and computer colour matching data.

- Instant flexo proofs.

- Easy to use – easy to clean.

- Excellent repeatability.

- Reduces press down-time.

- Fully interchangeable rollers up to 500 screen.

- Hand and automatic versions available.

Automatic version is ideal for computer colour matching. Hand version is recommended for visual colour matching.

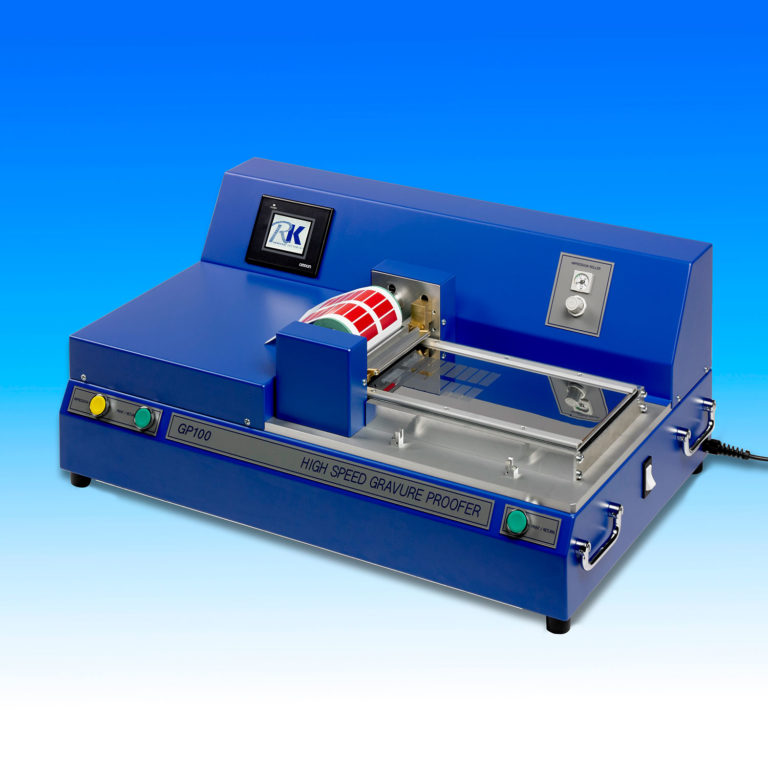

GP100 (High speed gravure proofer)

High quality proofs using gravure inks of press viscosity are produced instantly using the new GP100. Featuring a microprocessor controlled servo drive and pneumatic operation, electronically engraved printing plates and variable printing speeds of 1 to 100m/min, this is an essential tool for all those involved in the manufacturing or use of liquid inks. Ideal for R&D and computer colour matching data, quality control and presentation samples, the GP100 is very easy to clean.

- Any flexible substrate can be printed.

- Excellent printability ensured by the high speed of 100 m/min.

- Quick release Doctor Blade for ease of cleaning

Results ideal for computer colour matching or spectrophotometer readings.

Paste Ink Proofer

Accurate proofs produced in a single operation.

No messy weighing or measuring of inks, unlike other proofers.

Two inks may be proofed simultaneously for comparison.

Complete inking/proofing/cleaning cycle only 2 – 3 minutes.

Multiple proofs easily obtained using any substrate.

Reduces press down-time.

Results ideal for computer colour matching or spectrophotometer readings.

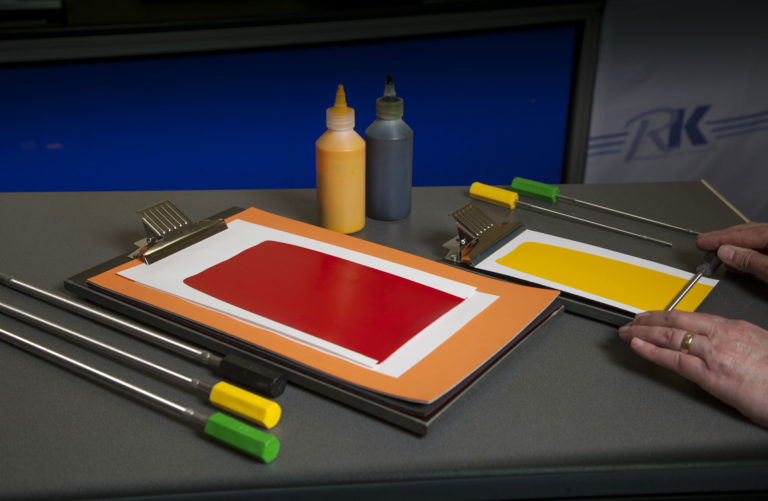

K Hand Coater

The K Hand Coater provides a simple but effective means of applying paints, printing inks, lacquers, adhesives and other surface coatings onto many substrates including paper, board, plastic films, foils, metal plates, glass plates, wood etc. Two or more coatings can be applied side-by-side in a single operation making the system ideal for comparing products.

- Simple, economical.

- Will deposit from 4 to 500 micron wet film thickness.

- Good repeatability with special impression bed.

- Stainless steel rods and wire used for K bars.

- K bars are numbered and colour coded.

- Two or more products coated simultaneously for comparison.

Recommended for visual assessment of properties e.g. colour, gloss etc.

K Control Coater

The K Control Coater is widely used for the application of paints, varnishes, adhesives, liquid printing inks and many other surface coatings to produce quick, accurate and repeatable samples. These may then be used for quality control and presentation purposes, R&D, computer colour matching data etc.

- Controlled speed and pressure ensures repeatable results.

- Coating by wire wound bars or gap applicators.

- Two models offer coating areas of up to 170 x 250mm or 325 x 250mm.

- Multiple coatings in one operation for comparison purposes.

- Standard coating speeds infinitely variable between 2 and 15m/m in.

Recommended for database and sampling use for computer colour matching, spectrophotometer readings, or other instruments.

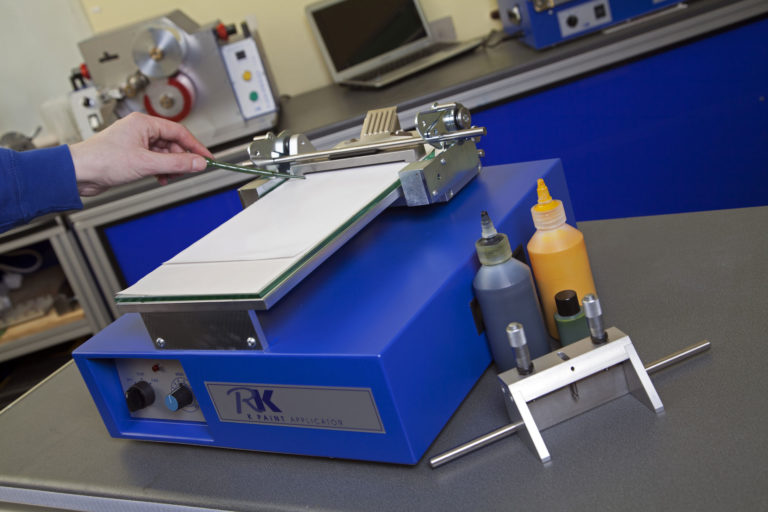

K Paint Applicator

Used for the application of paints to produce highly accurate and repeatable coatings in an instant. The machine uses gap applicators to coat onto paint test chartes, steel panels and many other substrates. This may then be used for many applications including quality control, weather testing, opacity and other standard tests such as colour matching and customer presentation samples.

Controlled speed and applicator pressure for highly repeatable results.

A custom version of the K101 created especially for paints etc.

Accommodates most applicators including Bird, cube, 4-sided, micrometer adjustable etc.

Supplied with float glass bed to ensure perfect flatness.

Vacuum, magnetic and heated beds also available.

Conforms to ASTM D823-92.

Esiproof

This is a precision manually operated instrument for producing realistic, high quality flexographic proofs. Applications include colour proofing for both customer approval and spectrophotometer colour analysis readings. Use of a doctor blade enables the proofing of all flexo inks, including high viscosity, UV curing. Both steel and ceramic anilox rollers are easily interchangeable. Spring loaded pressure control for ease of use and repeatability.

- Single screen or banded ceramic anilox rollers available.

- All commercial inks and substrates can be accurately proofed.

- Compact size makes it ideal for on site troubleshooting.

- Micrometer version available.

Recommended for visual colour matching.