Navigating in the many possible ways of applying different coatings can be quite a struggle. Let CoPriTech help you on the journey from idea to selecting the right production equipment.

Pilot Coaters

Small scale complete Coating Machines typically used laboratory use, for reseach & development, sample creation and pilot lines. Can be customized with most types of coating applications.

Precision engineered coating machine, designed to print, coat and laminate all types of flexible webs such as papers, films, and metallic foils on a reel-to-reel basis. With the ability to apply various coatings such as inks, paints, varnishes, adhesives both solvent and water based, by various application methods.

Flexo Coating

Flexo Coating Machines, Flexo Coating Units, Drying Hoods, Chamber Doctor Blade Systems, Ink Pumps, Automated Cleaning or said in another way; “Everything you need to apply Coating with Flexo”

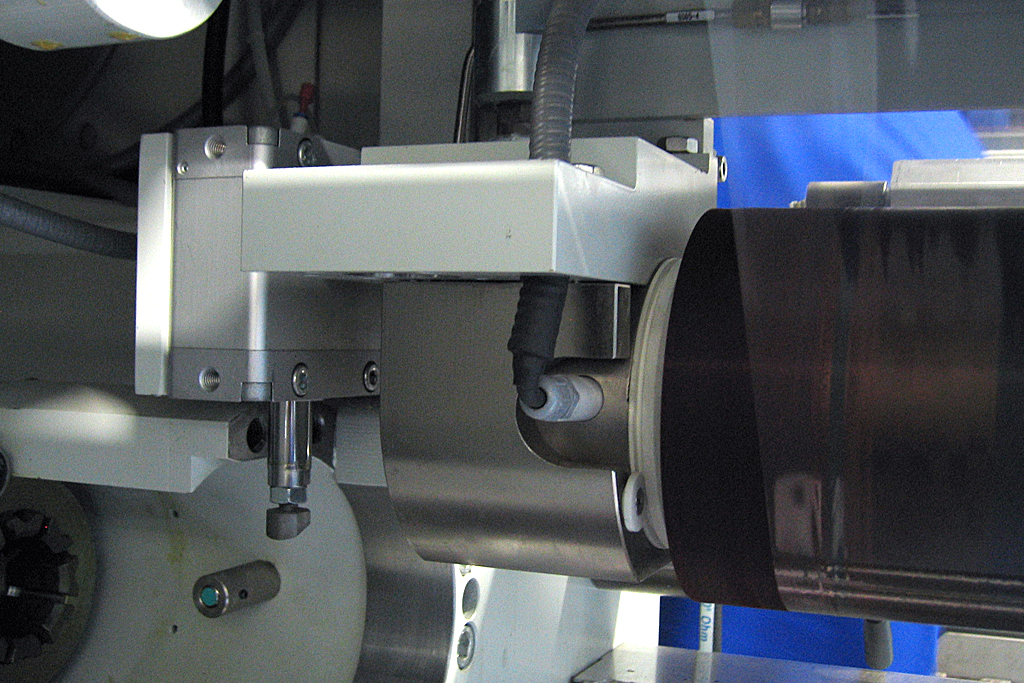

Gravure Coating

Full standalone Gravure Coating Machines and individual Gravure Coating Units.

UV Hot Melt Coater

UV/PSA (acrylic) Hot Melt Coating does in some cases have several benefits over conventional solvent-based and water-based adhesive coating methods.

Typically this application could be the right choice if you are looking for a cost-effective, low energy consuming, small footprint solution that can be operated by a single person with short make-ready and reduced waste.

Corona & Plasma

Do you need improved surface adhesion of your polymer substrates to make them perfectly coatable?

Do you want to apply a “Plasma Coating” or “Plasma Primer”? Some materials/substrates reacts better with different gasses than the Oxygen already present in the air around us, enabling different molecyles to be created on the surface. In this way the cemistry can be designed to bond better with Coatings, Adhesives and other applications.

We recommend using the Corona and Plasma systems from the inventors of the technology and still the technology leaders today!

Dryers

A full range of dryers, web dryers capable of drying using gas, thermal oil, steam, or electricity.

The nozzles have been computer modelled to give the optimum heat transfer and inverter driven fans come as standard to give additional control over the drying process.

Dryers can be combined the the HPDU for additional energy and CO2 savings.

Electro Static Equipment

Anti static, discharging and charging systems all have their place in the different steps of a coating production.

Where most use anti-static equipment especially for polymer substrates (films) a great benefit can also be achieved by not just removing the static charge, but instead controlling it to the level that is beneficial for perfect coating transfer.

Additionally charging the substrate to adhere to itself removes the need for tape or adhesives when splicing!

Chamber Doctor Blades & Ink Handling

Chamber Doctor Blade Systems both as a supply with new machines or retrofits on existing coating machines.

Automatic Ink Handling Systems (Intelligent Pumps) for High viscosity, High flow, high pressure, high speed or high temperatures.

UV, Waterbase, Solvent or E-beam.