Flexo Inline Printing

Flexo Printing Machines, Flexo Printing Units, Chamber Doctor Blade Systems, Ink Pumps, Automated Cleaning or said in another way; “Everything you need to print in Flexo”

Gravure Printing

Full standalone Gravure Presses and individual Gravure Units.

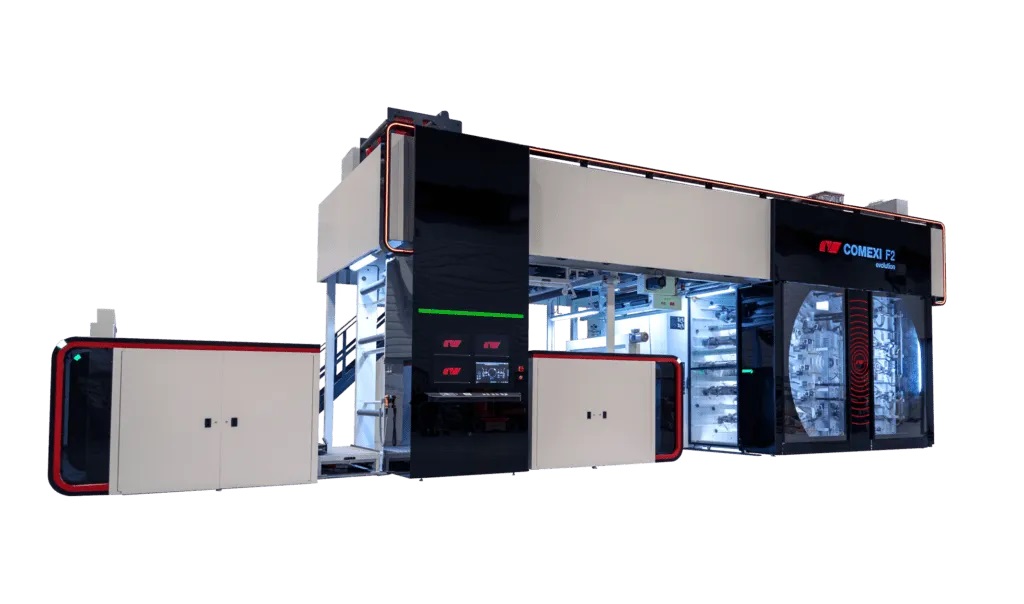

Flexo CI Printing

Flexo Central Impression Printing Machine. Up to 10 colors at 600 m/min. 400-1.350mm Print Repeat. Max Print width 1.670mm

Inline Color Measurement

Precise color control in running printing process. The color measurement systems use a non-contact spectrophotometer to take accurate measurements of colors during the printing process so you can respond quickly to issues, save money, and protect your branding.

Bridge Adapters

Pneumatic and Hydraulic Adapters for larger print repeats. Dramatically reduce bouncing with this high quality bridge adapter made from carbon fiber. Run 30%-100% faster on the same jobs before expiriencing bouncing problems.

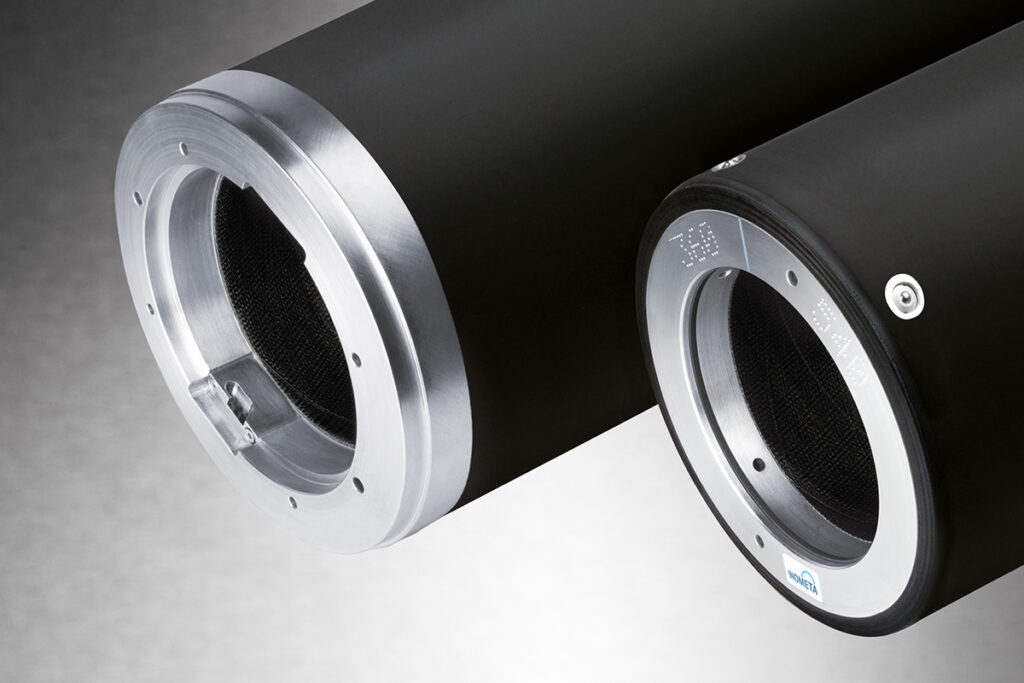

Anilox Rollers and Sleeves

Anilox Rollers and Sleeves that are significantly easier to clean and lasts longer. Special designs for high speed.

Offset CI Printing

Offset on a Central Impression roller! 8 colors (7 offset EB + 1 Flexo EB). Max repeat 930mm, 300 m/min. Max wed width 1.100mm.

It offers completely solvent-free printing and increases the recyclability of the packaging. Very high print resolution, where very fine lineatures are possible.

Corona & Plasma

Do you need improved surface adhesion of your polymer substrates to make them perfectly printable?

We recommend using the Corona and Plasma systems from the inventors of the technology and still the technology leaders today!

Flexo Plate Mounting

Easy to use plate mounting and de-mounting systems for printers looking to increase efficiency and standardisation between operators.

Ranging from manuel but still ergonomically and super easy to use to fully automated with the possibility to integrate with surrounding systems.

Drying (Hot-Air)

Printing with solvent and waterbased inks requires the right drying system, which often limits the productivity!

Hot-air drying systems can be designed to a specific application removing the speed limitations! Remember air velocity eats air temperature for breakfast!

Powered by electricity, gas or oil the right solution can be designed also to fit your economical or emission goals.

Dryers can be combined the the HPDU for additional energy and CO2 savings.

Electro Static Equipment

Anti static, discharging and charging systems all have their place in the different steps of a printing production.

Where most use anti-static equipment especially for polymer substrates (films) a great benefit can also be achieved by not just removing the static charge, but instead controlling it to the level that is beneficial for perfect ink transfer.

Additionally charging the substrate to adhere to itself removes the need for tape or adhesives when splicing!

Vision Systems

Web Inspection (Partial & 100%), Surface Inspection, Video Web Monitoring, Quality Control, Defect Detection, Register Control, Colour Management, Colour Measurement….

Flexo and Gravure Proofing Machines

The Proofing Machiness offers a high speed, operator-friendly machine for the production of proofs using water, solvent or UV inks. It is an essential tool for all those involved in the manufacture and use of flexo/gravure inks. Ideal for quality control testing to ensure consistency of performance of inks and substrates over time, presentation samples, printability of substrates, R&D including product and commericial viability, and computer colour matching data.

Chamber Doctor Blades & Ink Handling

Chamber Doctor Blade Systems both as a supply with new machines or retrofits on existing printing presses.

Automatic Ink Handling Systems (Intelligent Pumps) for High viscosity, High flow, high pressure, high speed or high temperatures.

UV, Waterbase, Solvent or E-beam.